We are excited to announce the latest release of CAD Exchanger 3.24.7, bringing powerful new features and improvements to enhance your experience with CAD data. Let’s explore the highlights:

CAD Exchanger SDK and Lab:

- Support of new format versions: Inventor 2025, Creo 11, and Siemens NX 2406;

- Support of CATIA .cgr files as external references.

Manufacturing Toolkit:

- Introduction of the 2D nesting functionality to optimize the placement of multiple freeform 2D shapes on a sheet;

- Recognition of stepped holes and pocket types in CNC machining;

- Improvement of the unfolding process for sheet metal parts with embossing.

CAD Exchanger SDK and Lab updates

Inventor 2025, Siemens NX 2406, and Creo 11 new versions

Our team strives to keep up with proprietary formats and provide you with import of the latest versions, helping you stay up-to-date and collaborative. In this release, we’re excited to announce the support of 3 formats: Autodesk Inventor 2025, Siemens NX 2406, and Creo 11. Read our documentation to learn more about the import scope, file extensions, and known limitations.

Support of CATIA .cgr files as external references

With this update, both CAD Exchanger SDK and Lab support CATIA .cgr files as external references. Previously standalone, these mesh files are now loaded directly within the model assembly. As a result, the lightweight model can be easily shared with counterparties without revealing the complete model construction details.

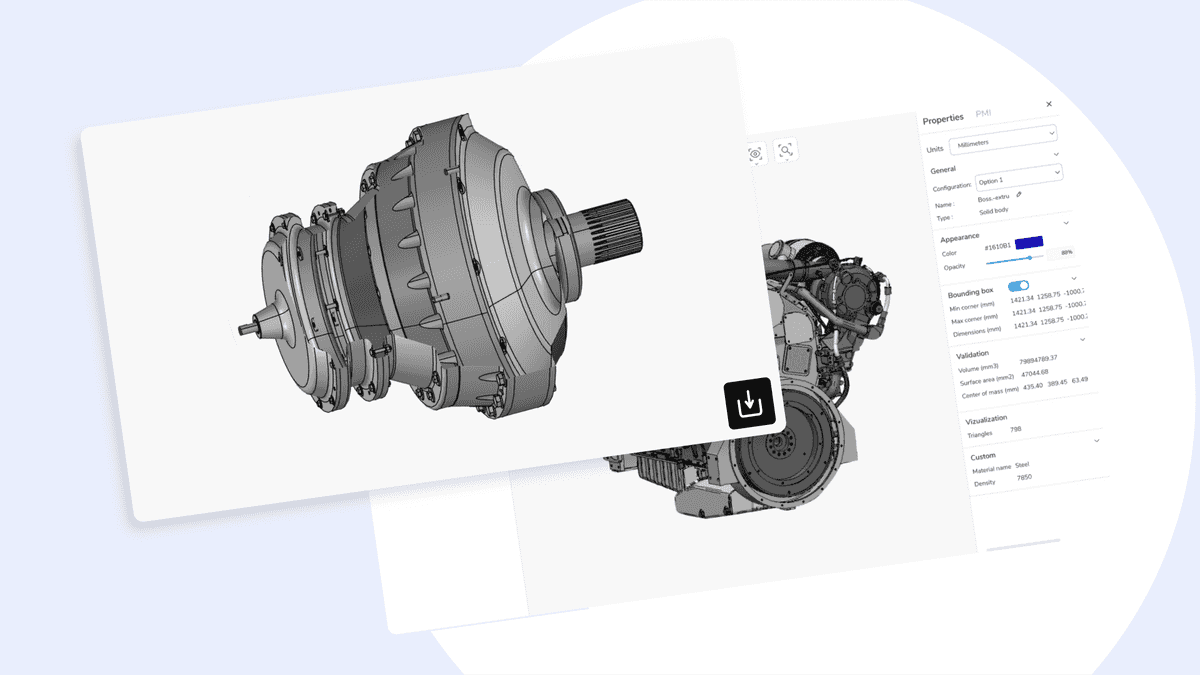

Resolved export-to-image issue in Lab

Previously, when exporting a model to an image, the first model would export successfully, but opening a second model and attempting to export would cause an error. Now, each export creates a temporary new scene, which resolves this issue and improves optimization. Additionally, if any parts of the model are hidden, the exported image will accurately reflect these visibility settings.

We’ve also resolved the file extension conflict where Creo files were mistakenly opened as NX files and vice versa, causing crashes. Now, each format is correctly identified, providing a smooth user experience.

Removed OpenGL dependency from core library in SDK

We've optimized our core library by removing its dependency on OpenGL (Open Graphics Library). Previously required for converting PMI to mesh representation, it has now been moved to the CadExView library. This change allows users who don't need visualization or generating screenshots to skip OpenGL installation and simplify SDK deployment on servers without GPUs.

Format improvements

As usual, we have added numerous improvements to file formats.

-

CATIA: fixed a regression when some B-Rep bodies were not imported, fixed crashes:

- when importing a file with missing external references;

- caused by infinite parametric lines;

- during parsing of an external link from the cache.

-

Creo: added support of .asm file extension;

-

DWG: added support of display order for hatching, text, and dimension (for SDK users only);

-

IGES: fixed the behavior of the SkipBlank import parameter so that it is taken into account when reading hidden (blanked) entities;

-

NX: improved recognition of suppress property, which caused some parts to be missed;

-

STEP: improved import of surfaces that use flat 3D curves as P-curves;

-

SLD: extended view bucket parsing to a wider range of versions.

Manufacturing Toolkit updates

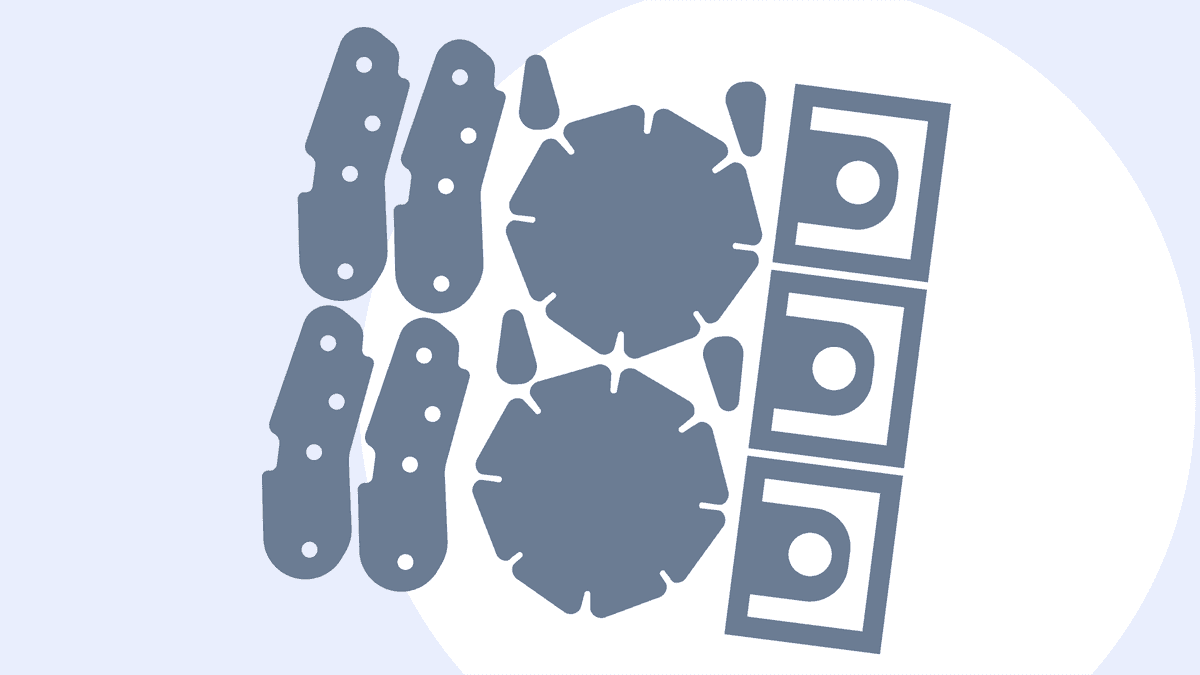

2D nesting introduction

We are excited to announce a completely new functionality in our latest release: 2D nesting. Now, you can optimize the placement of multiple freeform 2D shapes on a sheet, maximizing material usage and minimizing waste. To enable this, we’ve introduced a new drawing API to traverse and query 2D drawing data from the model.

The process starts from calculating layouts based on specified parameters and material properties. Once they are defined, our algorithm generates an optimal arrangement of patterns across the materials.

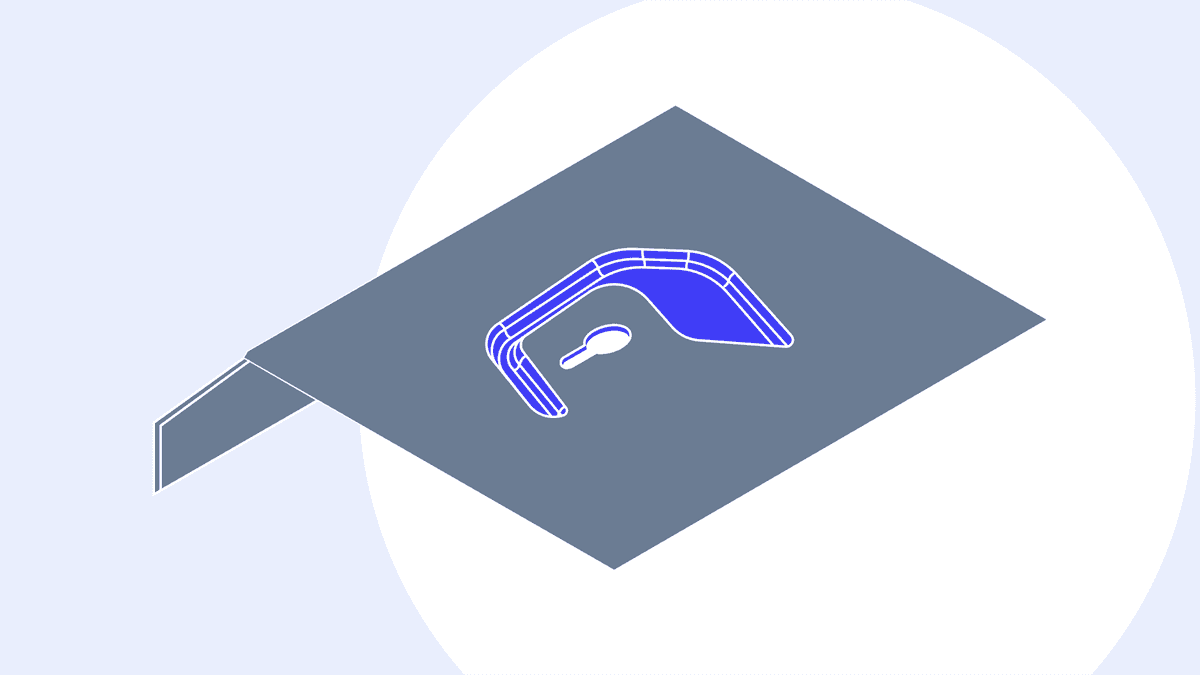

Improved unfolding sheet metal parts with embossing

Previously, sheet metal parts with embossing were not processed correctly, leading to inaccurate results during unfolding. To address this, we developed a dedicated algorithm to ensure that embossing is handled correctly. This improvement allows you to obtain accurate data during the unfolding process, significantly enhancing the reliability of sheet metal part processing.

We have also improved the processing of B-spline surfaces, allowing you to generate more precise flat patterns from intricate 3D shapes.

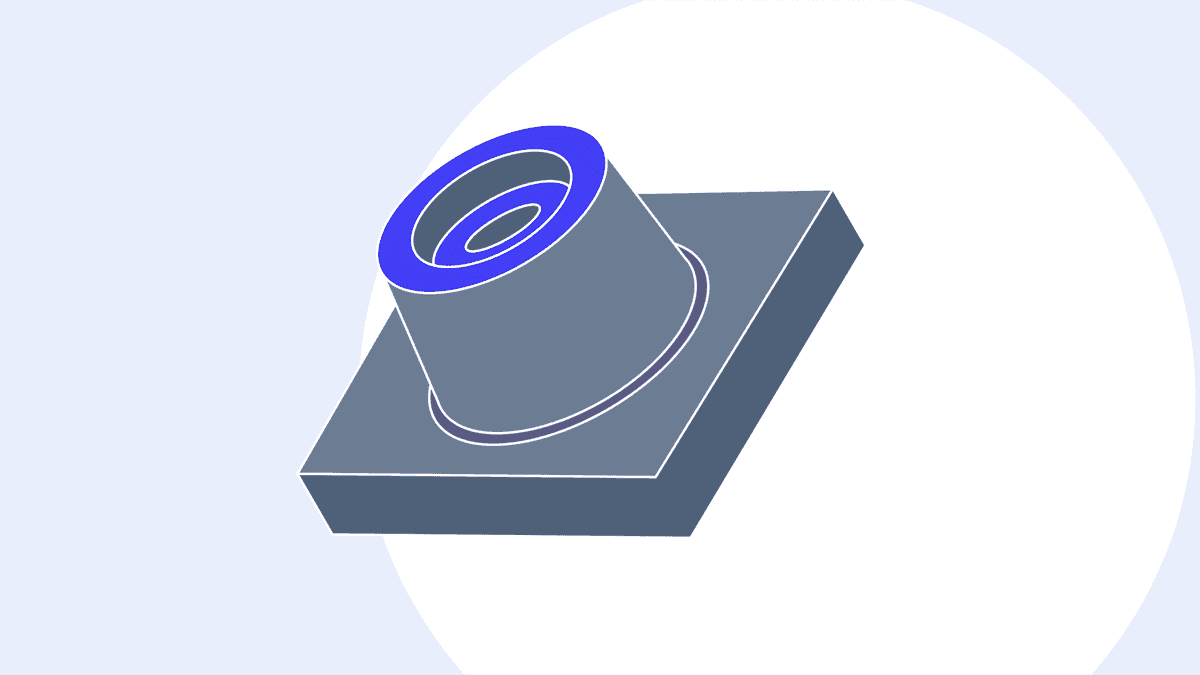

Recognition of new features and types in CNC machining

This time our main goal was to improve the recognition of holes and pockets. Previously, one stepped hole was recognized as separate features, but now it is considered as a single one with sub-features. Additionally, there is a new typification for pockets, which includes closed, open, and through types. We have also improved the recognition of holes, correcting cases where some of them were previously identified with the wrong type.

There are also some minor changes in CAD Exchanger SDK and Manufacturing Toolkit. To get the full list of the 3.24.7 updates, read the CHANGES.txt file.