Today, there are about 440 active nuclear power reactors and 50 more under construction. Apart from commercial and research power plants, nuclear energy is powering submarines, surface vessels, spaceships, isotopes production in food, agriculture, medical and other industries. The ubiquity of nuclear energy brings about specific challenges - decommissioning and waste management. The complexity of these challenges is not something a lot of people are aware of - each reactor produces up to 30 tonnes of used fuel annually and decommissioning takes 20 years on average requiring intricate planning and high expenses.

Both defueling and deconstruction impose numerous organizational and security challenges for the plant owners. How big would be the radiation exposure? In what order should the components be dismantled? How many man-hours and what type of equipment is required? What are the optimal radiation-protective materials? All these questions lie within the competence of Cyclife Digital Solutions (hereafter called Cyclife DS), a decision-support subsidiary of Cyclife Group EDF. The latter has been performing management of nuclear waste and facilities treatment for over 30 years with 9 ongoing decommissioning. The company has three industrial sites in France, the United Kingdom, and Sweden, as well as Cyclife Engineering and Cyclife DS.

Guillaume Chouvenc

Cyclife Digital Solutions. 3D simulation for interventions

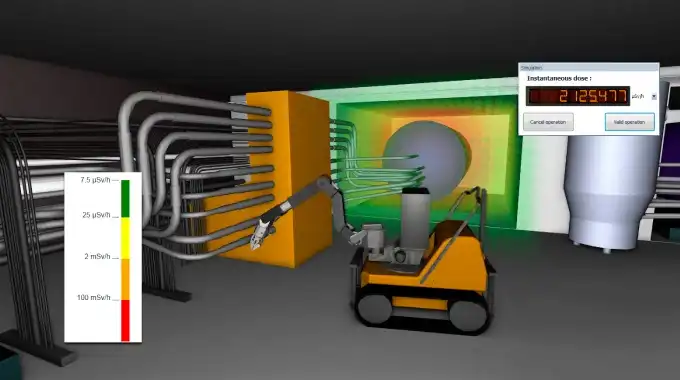

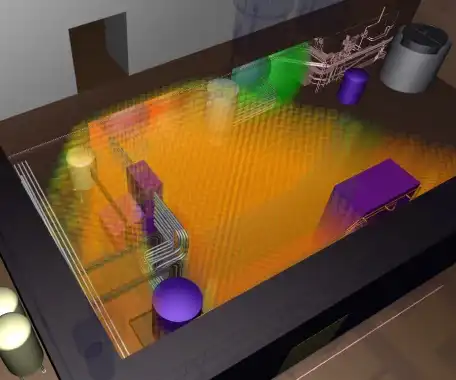

To help customers analyze and optimize the performance and reliability of nuclear facilities, Cyclife DS offers a collaborative real-time 3D simulation software - DEMplus® for nuclear.

The tool allows planning and tracking of operations at the nuclear facility, whether it’s construction, maintenance, or decommissioning. DEMplus® maps such factors as radiological sources and screens, equipment-environment collisions, equipment performance, waste's physical and radiological characteristics. This comprehensive analysis makes it possible to calculate the radiation dose, improve processes capacity and accessibility, and elaborate an optimum scenario in the terms of safety, cost, and duration.

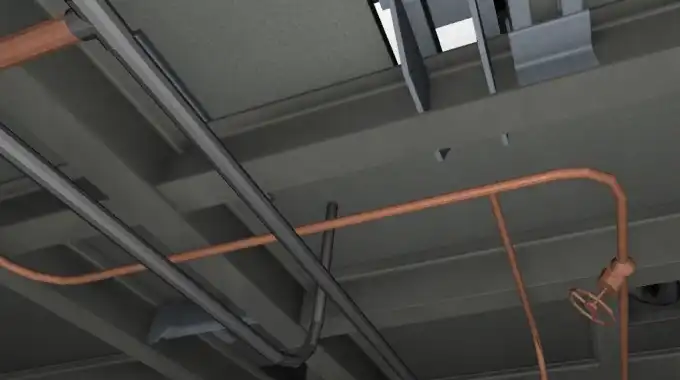

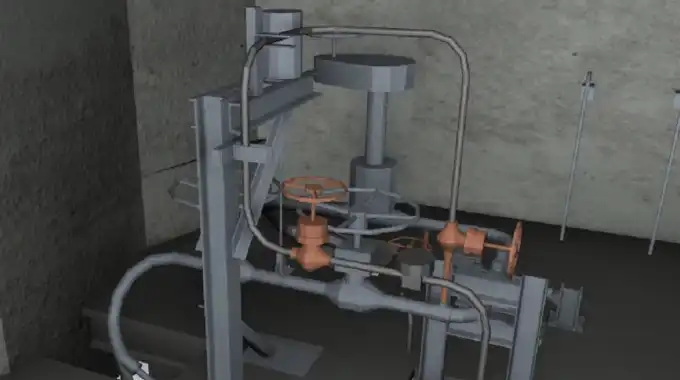

DEMplus® for nuclear. Establishing CAD inventory

DEMplus® simulation starting point is a 3D model. Cyclife DS customers need to import their 3D models to establish physical, radiological, and kinematic inventory. Given the diversity of processes involved, it might be civil engineering objects, piping, tanks, mechanical equipment, electric tools, HVAC element, etc. 3D models also vary in the way they are acquired: 2D plans reassemblies, 3D scans (drawing scatter plots), photogrammetry (reassembling by triangulation), and other data sources.

DEMplus® customers use various CAD software to create and manage their 3D models. Therefore Cyclife DS sought to provide support for the most common formats, STEP, IFC, and SolidWorks. The team was looking for a reliable software library that would enable CAD import while maintaining geometry integrity, scene graph, names, colors, materials, and other objects properties.

CAD Exchanger SDK. Non-invasive integration

Cyclife DS aimed to add support for the STEP, IFC, and SOLIDWORKS files within DEMplus®. The solution had to be "out-of-the-box", requiring minimal integration efforts. After some consideration, the CAD Exchanger SDK C# library was deemed the best option.

“It is a reliable, well-built multi-language SDK with very good documentation, which allows direct integration into our software,” says Guillaume Chouvenc, R&D Engineer in Cyclife DS.

CAD Exchanger provides the following advantages in terms of empowering 3D applications to visualize and analyze CAD models:

- CAD Exchanger products are truly developer-centric, which manifests itself in easy-to-follow documentation and tutorials.

- Flexible licensing models suitable for: distribution, SaaS, or in-house usage.

- No supplementary actions need to be undertaken except for straightforward API integration.

- CAD Exchanger allows users to import 25+ 3D formats and process all the necessary 3D data.