Problem

Design teams engaged in new projects may often have a poor understanding of future production costs and defer cost estimation to later stages of the product lifecycle. However, lack of early understanding of production costs can lead to underestimated real expenses and lost opportunity to reduce costs locked in by early design decisions. In short, not having early-stage manufacturing cost estimates can lead to reduced competitiveness and eventually to business model failure.

Karen McRitchie

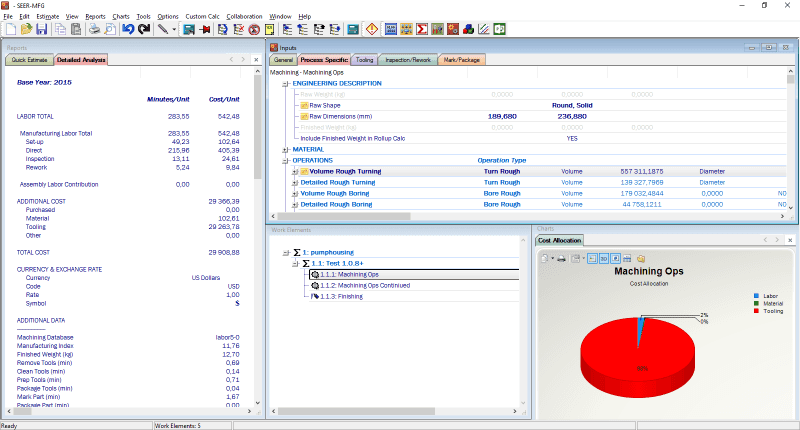

To help businesses overcome this problem and reduce design-to-production time Galorath Incorporated developed its unique ‘cost-model’ that enables estimation of manufacturing costs at early design stages. This know-how was implemented in the SEER for Manufacturing (SEER-MFG) application and has been continuously improved and developed by Galorath for more than 20 years. SEER-MFG is a process-centric costing approach using product data such as dimensions, materials and manufacturing operations to build cost estimates. SEER-MFG estimates are comprehensive covering labor, material and tooling costs, providing insight into how different manufacturing process steps contribute to the overall cost. The application has received broad adoption, but particularly in the aerospace market. The customers include Boeing, Airbus, Textron Aviation and many other manufacturers worldwide. The application accepts numerous precise data and in return generates accurate cost estimates helping manufacturers reduce their expenses by iteratively fine-tuning the product design.

While the SEER-MFG approach is effective, users had to manually collect and enter part data, even when this information was available in 3D models. This time-consuming effort presented both a challenge and opportunity, to be able to leverage available data enabling rapid and accurate cost estimates.

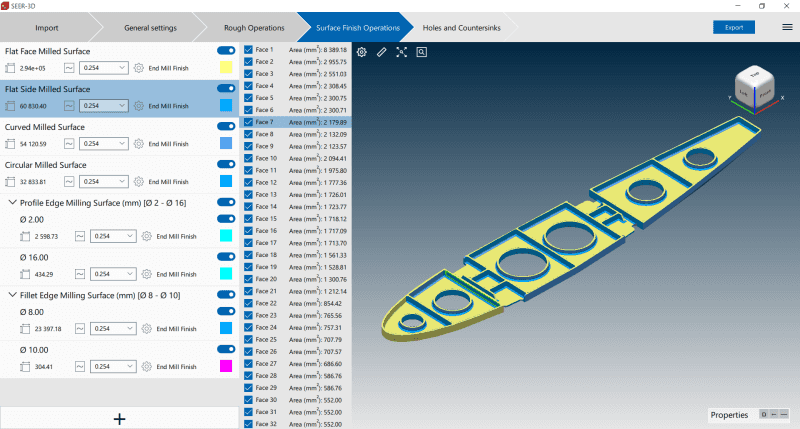

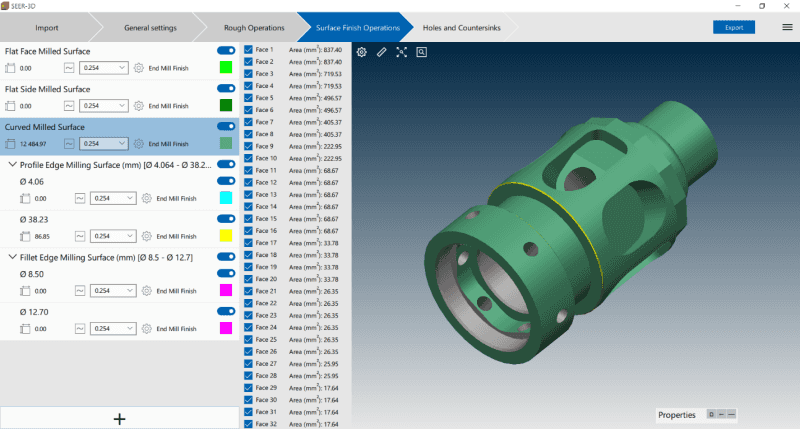

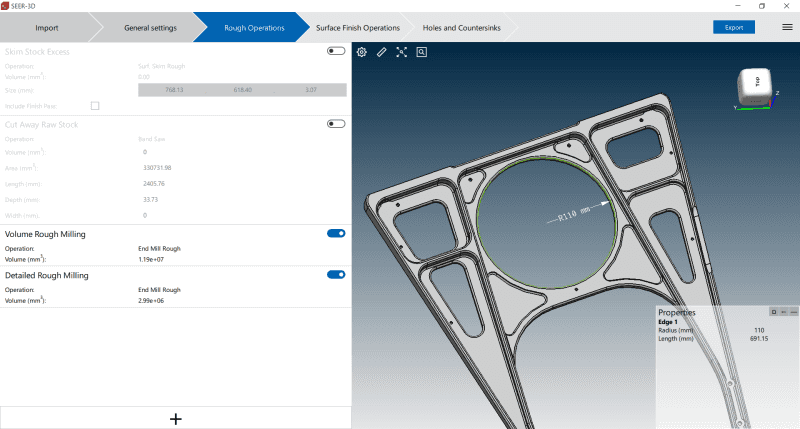

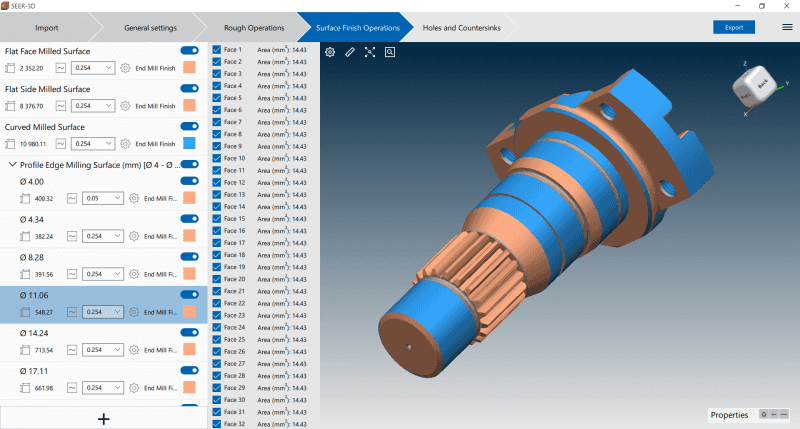

In today’s competitive landscape, reduced time-to-market is often a great competitive advantage. So Galorath has strived to help its customers by increasing their productivity by attempting to automate many users’ actions. With that in mind, Galorath approached the CADEX team to discuss the possibility of developing an application that would collect the required application data directly from 3D models and feed this into the SEER-MFG ‘cost model’ engine. This laid down a foundation for SEER-3D, a highly interactive graphical application that automates user’s actions and increases their productivity and accuracy.

Solution

SEER-3D, powered by CAD Exchanger SDK, is able to extract bounding boxes, volumes, surface areas and surface geometries and other information automatically. All this is done without human participation, thus significantly reducing the time needed to generate the estimates.

STEP is used as the input file format, since it maximizes interoperability with all major CAD systems like CATIA, NX, SolidWorks, Inventor, Pro/Engineer, etc. Special attention has been paid to design an intuitive easy-to-use user interface (UI) which significantly reduces the learning curve. The wizard-like interface guides the user through the manufacturing process, allowing the user to fine-tune machining operations like drilling, milling, surfacing etc. Analyzing the 3D model, the application automatically identifies operations required to manufacture the part and provides the user with tools to redefine or adjust computed parameters. At the last step of the SEER-3D workflow, collected data is automatically fed into SEER-MFG which users are typically already familiar with.

As a result, collecting data and generating cost estimates can take just a few seconds which allows users to iterate on designs much faster, significantly speeding up the costing and design process.

Development

To build a great product you have to listen carefully to your customers. During the development of SEER-3D, we closely collaborated with the Galorath team. Their experts did a great job regularly interviewing SEER users and exploring their needs and interest in additional functions like measurements, surface re-groupings, new operations, etc. After some iterations, we rolled out a preview-version that was presented to a focus group of users. During those iterations we received a lot of useful feedback and ensured market fit of the product. After a while, a production version was released into the market.

Value

As a result of our collaboration with Galorath the SEER-3D application was shipped on time and successfully distributed to users. First impressions from users were highly positive. Users highlighted the following advantages:

- Productivity growth. Due to automation of manual operations users save significant time entering data. What used to take hours of human work now takes a few minutes or even seconds.

- Manufacturing cost reduction. Thanks to faster and accurate estimates large vendors are now able to accurately forecast their costs and have leverage in negotiations with their suppliers on reducing part pricing. Some reported savings of millions of US dollars thanks to using SEER-3D. This has tremendous return-on-investment effect.

- Ease-of-use and CAD neutrality. Thanks to the simple step-by-step workflow users are learning the tool quickly without long training classes. Standalone work outside of CAD systems allows more users to utilize CAD data within companies who previously could not participate due to limited CAD system licenses.

All this helps Galorath win new customers and expand penetration into existing accounts.

Next steps

SEER-3D is rapidly being adopted by both the existing SEER-MFG user base as well as those new to the process based costing methodology. One leading aerospace manufacturer is looking to generate over 10,000 part costings using SEER-3D, in support of high profile initiatives.

We continue to actively work with the Galorath team to expand the application capabilities. The roadmap includes additive manufacturing and other manufacturing processes, such as sheet metal, composites, multi-part and assembly support, and many other features to address growing user needs and to strengthen Galorath’s technical leadership.