Company overview

Karkhana.io is a contract manufacturing platform that offers high-quality manufacturing & project management solutions for custom parts, electronic manufacturing services (EMS) & box builds. The company collaborates with original equipment manufacturers (OEMs) and technology companies to establish manufacturing solutions, starting from the initial few hundred units of a product and scaling it up to mass production.

With a network of over 600+ certified suppliers and a broad range of manufacturing capabilities, Karkhana.io serves as a one-stop solution for all manufacturing needs. Karkhana.io offers a wide range of manufacturing services, including CNC machining, sheet metal fabrication, injection molding, casting, forging, printed circuit board assembly (PCBA), wire harness, and box build, delivering customized solutions for various industries with precision and efficiency.

Serving industries such as aerospace, automotive, energy, IoT, medical devices, electric vehicles, oil & gas, Karkhana.io provides tailored solutions to clients in India, North America, Europe, and the Middle East. With over 100+ customers and 5 million+ components produced, the company stands as a reliable partner, helping businesses scale their manufacturing operations with precision, efficiency, and innovation.

Rahul Arethiya

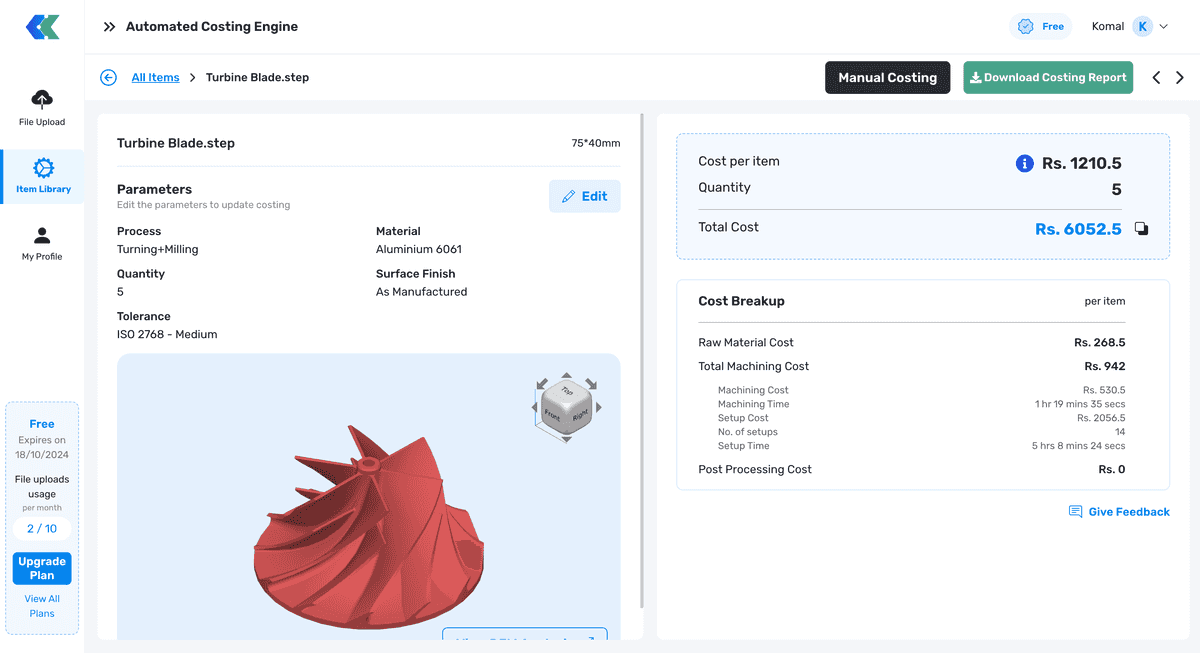

Automated Costing Engine (ACE)

Karkhana.io provides a digital ecosystem that optimizes custom manufacturing through automation, transparency, and seamless collaboration between buyers and suppliers.

At its core lies the Automated Costing Engine (ACE), a solution that transforms how CNC machining costs are calculated.

Karkhana.io’s Automated Costing Engine (ACE) provides accurate cost calculations for CNC machining parts. By analyzing the uploaded CAD models and using predictive algorithms, it estimates machining times and costs with precision. This innovative engine optimizes the costing process, giving users clear cost insights into their projects quickly and efficiently.

It allows:

- Analyze geometries and machining features.

- Predicts machining time based on configurable cost models (material rates, tolerances, post-processing).

- Generate a transparent cost breakdown, including setup time, raw material recommendations, and DFM insights.

The automated costing engine is powered by Manufacturing Toolkit, AI, and machine learning. This tool allows for rapid and accurate cost estimations based on the CAD data provided, minimizing errors and discrepancies that often occur between initial quotations and actual production costs.

Technology stack

In its platforms, Karkhana.io uses a client-server architecture, using microservices to efficiently manage various components of the manufacturing process, such as procurement or costing. Built on the Frappe framework, it uses Python for backend operations and React with TypeScript for the frontend, ensuring an efficient infrastructure. To further drive continuous improvement and precision, the company integrates methodologies such as Six Sigma and DMAIC in its processes.

Challenges

The company faced two major challenges in the Indian manufacturing ecosystem. The first one was the prolonged time required to receive quotations from suppliers. As Karkhana.io operates with a network of suppliers for custom manufacturing services, delays in receiving quotes meant slow responses to customer requests. This delay, often stretching to one or two weeks, was a major bottleneck in their operations. The company needed a solution to speed up this process and reduce dependency on manual quotations from suppliers.

The second challenge was the outdated and non-standardized costing methods used by suppliers. Karkhana.io worked with small to medium enterprises (SMEs) that often used, for example, manual calculations, leading to inconsistencies and inefficiencies in the pricing process. This made it difficult to establish a standardized and efficient costing process.

Solution

To streamline both challenges, Karkhana.io developed an automated costing engine, implementing the Manufacturing Toolkit at ace.kkonnect.io to extract essential geometrical and topological data that directly informs manufacturing costs.

By leveraging Manufacturing Toolkit’s ability to convert 3D CAD data into mathematical models, the company was able to provide rapid cost and cycle time estimations, reducing the reliance on manual calculations and minimizing discrepancies between quoted and final costs. In case the supplier thinks that the cost is not reasonable, he can always contact the company using the give feedback button.

Manufacturing Toolkit’s detailed documentation and the support provided by the CAD Exchanger team helped overcome initial challenges, ensuring a smooth implementation.

Now, besides order and parts management, the platform offers the following features based on Manufacturing Toolkit capabilities:

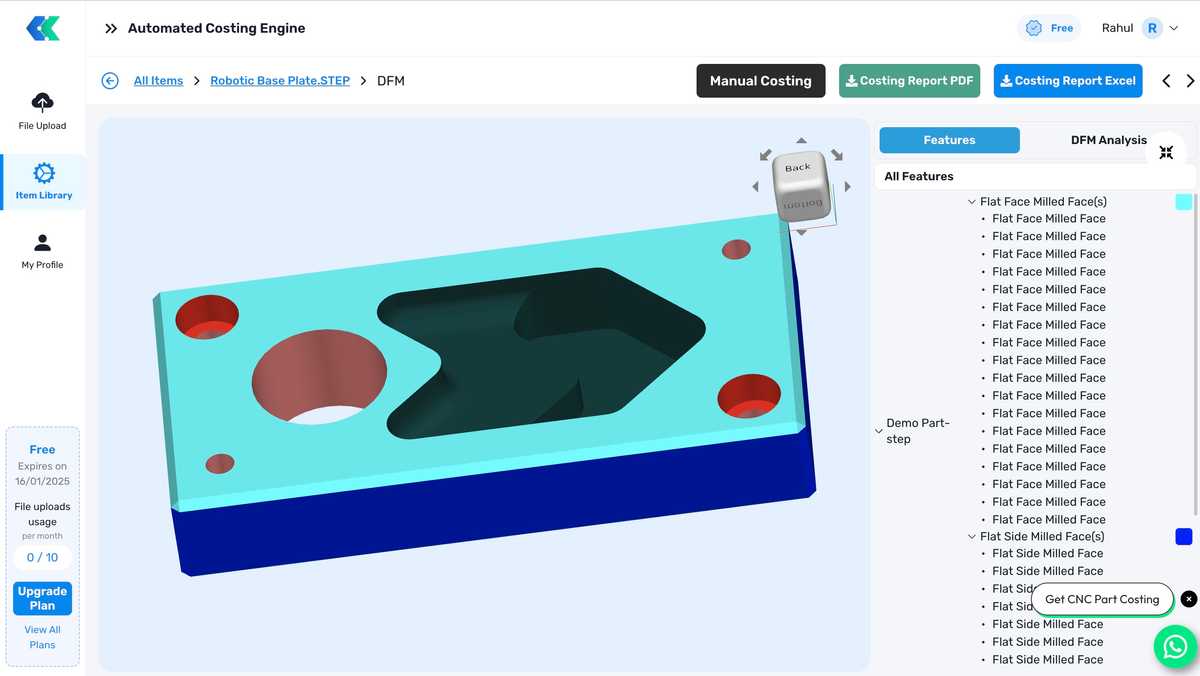

- Machining feature recognizer. It stands out as a key tool, allowing Karkhana.io to efficiently map various machining features within CAD files, enabling precise cost estimations.

- Design for Manufacturability (DFM) analysis. The DFM analysis offers detailed insights, identifying potential manufacturing issues early on, which is crucial for providing accurate quotes. Customers can also review designs by clicking the View DFM button to open an integrated 3D viewer.

This digitized approach enhanced the speed and accuracy of the estimation process, helping suppliers (many of whom lacked advanced tools) access sophisticated technology.

Resulting value

Manufacturing Toolkit has been successfully integrated into Karkhana.io’s automated costing engine for CNC machining. The resulting solution has noticeably reduced the time from order to production thanks to faster and more accurate quoting. Automating what were once manual tasks has saved considerable time, allowing the company to focus on scaling its solutions.

These days, Karkhana.io meets and exceeds customer expectations, delivering reliable solutions that save time and reduce costs in India’s fast-evolving manufacturing ecosystem. Looking ahead, the company plans to use other Manufacturing Toolkit capabilities, viewing this technology as a significant aspect of future growth.