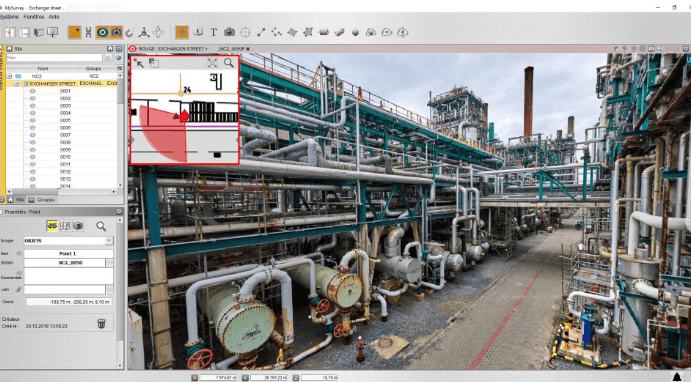

Quadrica is a fast-evolving French company, which provides solutions for displaying, managing and analyzing data from 3D scans and photoshootings. It was 2015 when it became pretty obvious that the market lacked an innovative and easy-to-use tool to quickly exploit 3D scan data. Created with very good knowledge of the field, Quadrica’s flagship product MySurvey became a perfect tool, focused on the user’s needs. The main objective of MySurvey is to use data from laser scans to allow user, be it an asset owner, project manager, or a technician, to make an intuitive visit of the infrastructures which effectively cuts production costs by reducing the number of people on site.

Gwendoline Le Pennec

MySurvey

Let us elaborate on some nuts and bolts of the functionality of MySurvey.

3D tour

My Survey is in the first place a tool which enables virtual tours. It allows user to view panoramic site views, move into a cloud of points or even import their own models there. As MySurvey exploits all available sources of information including point clouds, 3D models, high-definition photos, 2D shots, it provides to the user the most relevant and precise data possible. Virtual reality indeed!

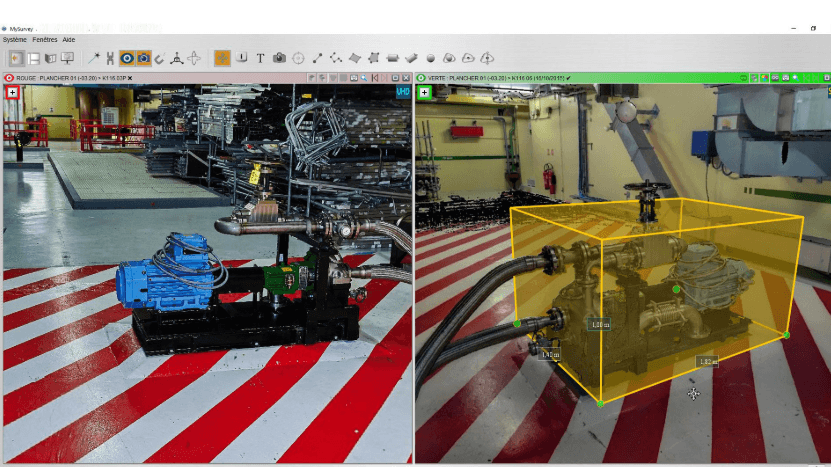

Measurements and modeling

MySurvey makes it possible to the user to measure distances, surfaces, angles intuitively, with an unparalleled accuracy. The opportunity of remote site exploration allows user to reduce the number of people on site, cut dosimetry and make the manufacturing processes more resistant to conventional hazards.

Inventory and Inspection

The technology of MySurvey allows user to virtually control the progress of their worksite and anticipate troubles. Moreover, within MySurvey environment it is easy to safely collaborate on data from laser scans, associating texts, images and links with them.

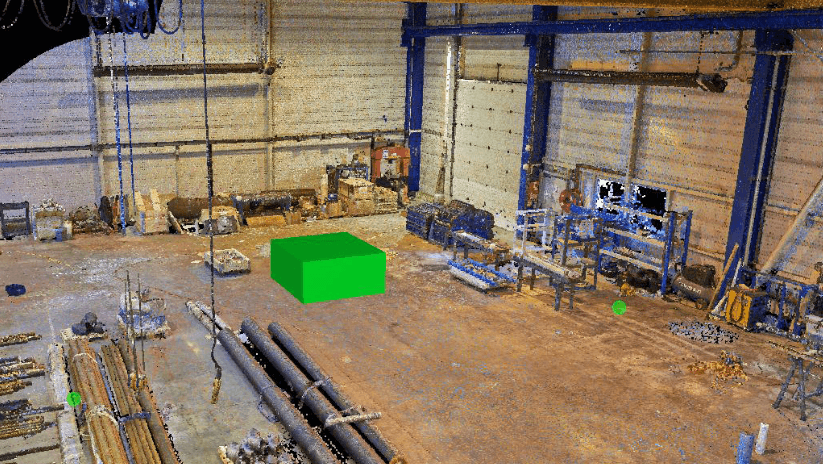

Challenge

One of the main objectives of MySurvey is to simulate the implementation of new equipment to reduce the number of site visits. To perform this, Quadrica’s team has to set the 3D models of equipment pieces into the point cloud generated from the site scanning. The result is the integrated view of the site with all the necessary equipment virtually implemented. The problem was that the 3D models would come in STEP format. To read those files they had to write a code for their own STEP importer, which is not only a time and effort-consuming process; it still couldn’t guarantee precise and fast files import.

Solution

So the company was faced with the choice: either to put their time and effort into making a STEP importer themselves, or to find an easier solution. And that’s when they decided to trust CAD Exchanger SDK with the process of reading 3D STEP files. The basic SDK package was just fine for Quadrica; and using Java they could easily integrate 3D models into any point cloud environment with no fear of losing a face or two.

Value

Giving us charge over the STEP importing processes Quadrica reduced risks of getting 3D models imported with errors and uncertainties. It eliminated costs of writing their own code for a STEP importer. Instead for this purpose they got CAD exchanger SDK, an easy-to-use and reliable application to match MySurvey, an equally simple and innovative solution.