The grand purpose of CAD Exchanger is compatibility between CAD, CAM, CAE, PDM, and other steps of a product life cycle. In the mid-1980's STEP format, also known as ISO 10303, was created with the same objective and became a common standard for CAD data exchange. Sure enough, STEP was one of the first formats supported by CAD Exchanger and the one with high priority for further improvements.

In 2016 STEP importer was boosted with parallel computations that dramatically reduced files processing time. Then, CAD Exchanger took consistent steps to provide full PMI support for this format in 2019-2020. The software finally enabled reading and writing of semantic PMI, graphical PMI, and PMI associations, as well as visualization of graphical PMI. And next up was STEP tessellated geometry support, recently introduced with AP 242.

Being the common tool of interoperability, STEP is frequently specified as a target format by CAD Exchanger customers. Below are several examples of projects during which the STEP conversion was added to the customers' applications.

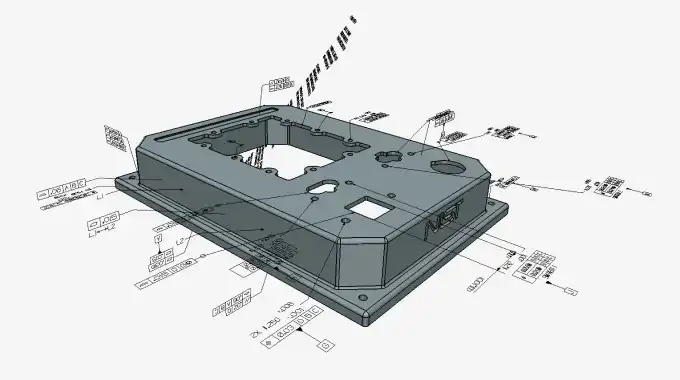

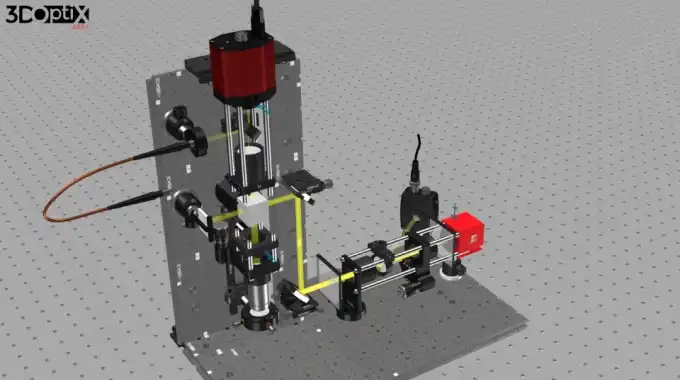

3DOptix: STEP to mesh

3DOptix, an optical design company, launched cloud-based software allowing users to create and simulate optical system designs. One of the key features of the tool was a possibility to upload customer’s optical parts and devices into the scene. That really meant converting traditional optomechanics formats (STEP, Parasolid, SOLIDWORKS) into mesh.

CAD Exchanger Cloud API proved to be a reliable tool for this purpose, providing consistent conversion and browser-compatibility.

Gil Noy

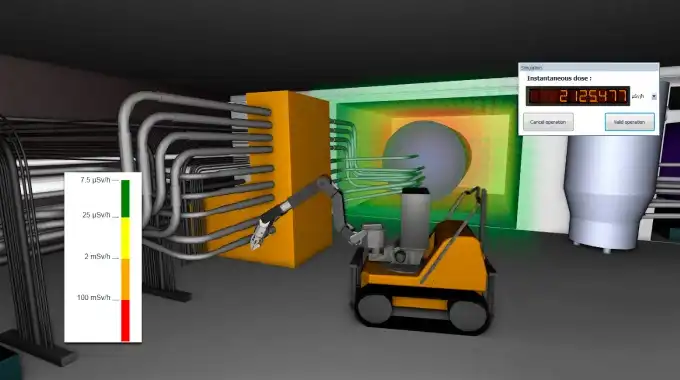

Cyclife Digital Solutions: STEP for nuclear intervention simulation

Cyclife Digital Solutions provides the nuclear facilities with a collaborative real-time 3D simulation software DEMplus® for nuclear. DEMplus® collates various factors to optimise construction, maintenance, and decommissioning of nuclear sites. To perform an insightful analysis it’s necessary to import all the equipment and infrastructure elements into the simulated environment.

Search for a suitable software led Cyclife DS to CAD Exchanger SDK, which now enables import of STEP, IFC, and SOLIDWORKS, visualization of CAD models, and their comprehensive analysis.

Guillaume Chouvenc

GCAS: STEP to X3D

GCAS Incorporated develops military and intelligence applications with focus on artificial intelligence, structural dynamics and acoustics, planning and scheduling, and probabilistic reasoning. One of dozens GCAS government contracts resulted in a simulation and modeling system CES (Corrosion Expert System), which identifies vehicle design issues leading to corrosion.

CES algorithm included several conversion steps for the original STEP models. CAD Exchanger enhanced the architecture with CAD Exchanger SDK and computational mesh generation add-on. This combination let automotive and truck designs be seamlessly converted to X3D, boosting CES performance and reducing its memory footprint.

Scott Woodson

OMRON: STEP for virtual factory simulation

Industrial automation leader OMRON elaborated Sysmac Studio 3D to help customers to configure and emulate complex production environments. Simulation empowers all the stakeholders to identify design flaws without launching a real production site, which leads to money and time savings.

Aside from a vast 3D components library, the software enables users to upload their own robots, machinery and other 3D objects. Import was implemented through CAD Exchanger SDK and covered STEP and IGES file formats as the most frequently used by equipment manufacturers.

Pere Llibre Turbr

RUHRSOURCE: STEP for 3D printing

CUR3D, the flagship product by RUHRSOURCE, was aimed to solve the most pervasive problem in the 3D printing industry - 3D models requiring hours of manual cleanup and optimization to be ready for 3D printing. CUR3D automatically processes 3D models within a couple of minutes, making them suitable for manufacturing.

Since the application is used by a wide range of customers, from automotive to AEC, RUHRSOURCE had a request for an SDK with a great choice of formats support. CAD Exchanger SDK enabled seamless processing of such CAD formats as STEP and IGES and increased CUR3D outreach to various industries.

Christopher Maiwald

With CAD Exchanger SDK STEP component, developers can enable files import and export in their applications making the most of the format:

- Compliant mapping of assembly and part structure, topology, and geometry into CAD Exchanger entities after import;

- Flexible import and export parameters (e.g., preferred B-Rep shape representation type and PMI import in the former case, external references usage and the length unit for the latter);

- Support of both b-rep and polygonal representations;

- Compliance with AP 203, AP 214 and AP 242, including PMI and tessellated geometry;

- Support of colors, layers, meta-data, and user-defined properties;

- Support of external references with a possibility to write either every part or both assemblies and parts to their own STEP files, “master” file containing product structure or only its roots correspondingly;

- Support of delayed conversion ensuring responsive application and better UX even for large files;

- Support of validation properties to control the quality of a conversion;

Enable other file formats with just a couple of lines of code and contact us at info@cadexchanger.com in case of any questions.