Conversion from Powermill to KOMPAS-3D is not supported yet :(

Learn more

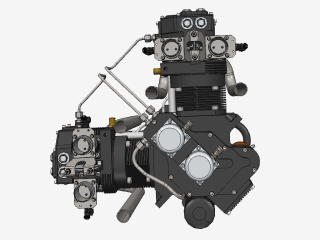

Powermill is a 3D Computer-aided manufacturing app developed by Autodesk Inc. It runs on Microsoft Windows and is used in many different engineering industries to determine optimal toolpaths to reduce time and manufacturing costs.

Powermill rapidly creates toolpaths on large, complex parts, works with surfaces, solids and STL meshes. It uses efficient roughing strategies and can create gouge and collision free toolpaths, which can be edited and optimized. The software obtains comprehensive range of finishing toolpaths, user-defined macros and templates for automated CAM, extensive library of tool types for use with 3- and 5-axis milling, and specialist tools for demanding industries and applications.

KOMPAS-3D is a flexible 3D modeling system that allows creating models by several methods, including the following ones:

Bottom-up modeling using finished components. Top-down modeling by designing components to match specific designs. Modeling based on layout drawings, such as kinematic diagrams. Or any combination of these modeling methods. These approaches allow creating editable associative models easily.

The KOMPAS-3D system has powerful functions for managing projects of thousands of sub-assemblies, parts, and standard library products. It supports all the capabilities of 3D solids and surface modeling that have become the standard among medium-level CAD/CAM programs.

How to connect Powermill with KOMPAS-3D?

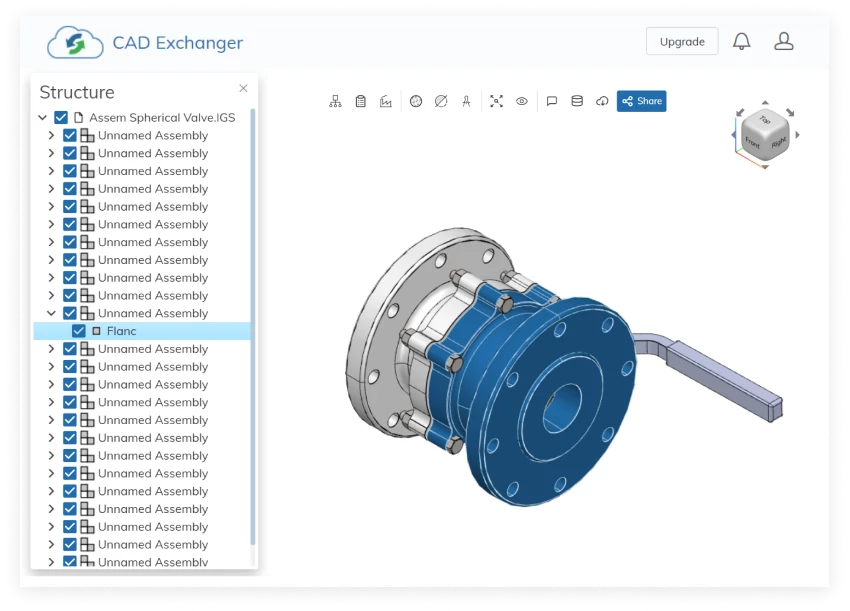

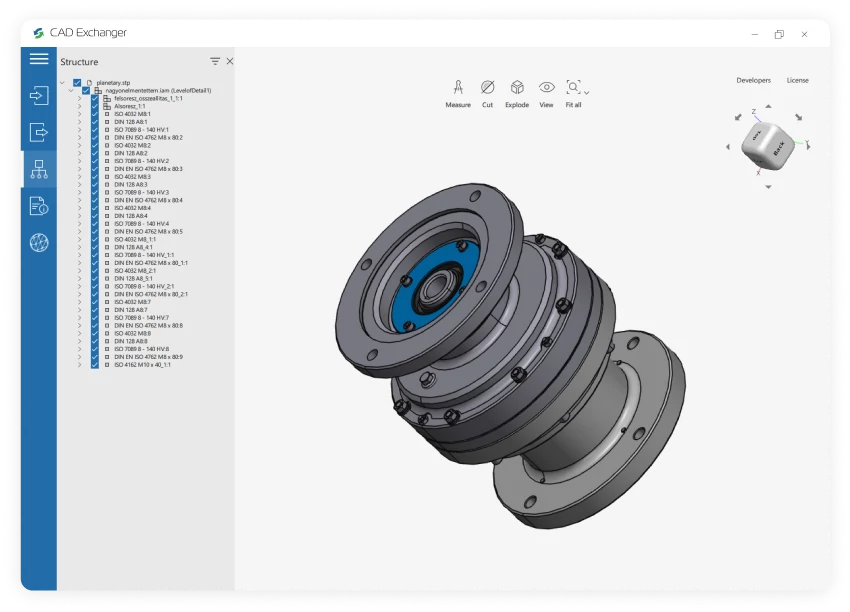

From Powermill to CAD Exchanger

From CAD Exchanger to KOMPAS-3D

From Our Blog

Everything you need to know about CAD file formats

A CAD file is an output of a CAD software, containing key information about the designed object: its geometry and topology representation, 3D model hierarchy, metadata, and visual attributes depending on the format of the file.

Read more

Integration with UNIGINE engine

This article explores the integration possibilities with the UNIGINE engine, a powerhouse in the realm of virtual simulation and game development. Learn how it can be used in applications built with the UNIGINE engine to import CAD and 3D models.

Read more

Manufacturing Toolkit and Web Toolkit enhancements, Unity performance optimization, renaming and rotating SDK examples in release 3.24.0

Explore the wall thickness at a specific point on a surface, enjoy four times faster Unity objects performance, and check out renaming and rotating examples in SDK.

Read more