Conversion from STEP to SOLIDWORKS is not supported yet :(

Learn more

STEP

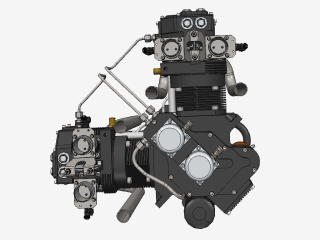

The STEP format is a neutral file format used for the exchange of data in the field of CAD. It can contain data, such as 3D geometry, product structure, attributes, tolerances, and materials.

Supported versions

Below you can find all the specific types of STEP files that CAD Exchanger supports:

AP203 focuses on mechanical design. It is used to exchange 3D models and associated information for product design and manufacturing processes.

Also known as the Automotive Design Standards, AP214 is used in the automotive industry. It includes additional features to represent complex assemblies and automotive-specific information.

AP242 is an advanced STEP version that supports the exchange of product information throughout the product lifecycle, including manufacturing, assembly, and maintenance.

Support of STEP in CAD Exchanger

During import and export, CAD Exchanger supports:

- B-Rep and polygonal representations;

- assembly structure, including via external files;

- names;

- user-defined and validation properties;

- PMI;

- colors;

- layers.

Follow this link to check out all the CAD Exchanger products.

Pros of the format

Interoperability

Since STEP is a neutral file format, it is not tied to any specific CAD software vendor. Almost any software that works with CAD data, and many programs that work with 3D data, can read or write this format.

Geometry and Data Preservation

STEP files are capable of representing complex 3D geometry, including curves, surfaces, and solids. They also store additional information, such as product structure, attributes, and metadata. This ensures that the integrity of the design is maintained during the exchange process, reducing the risk of data loss or conversion errors.

Long-Term Archiving

STEP files are widely recognized as a stable and reliable format for long-term data archiving. Their standardization ensures that the files will remain accessible and usable in the future.

Cons of the format

File Size

Due to their comprehensive nature, STEP files tend to contain a large amount of data, resulting in larger file sizes compared to other file formats. This can pose challenges when it comes to storage, sharing, and transferring files, particularly in cases where limited storage space or bandwidth is a concern.

The larger file sizes can also impact processing and loading times, especially when dealing with complex assemblies or intricate geometries. It may take longer to open, potentially affecting productivity.

Text-based format

The majority of STEP files are written as text files. While it allows for human readability and easy interpretation, it can introduce potential round-off errors in numerical values. These rounding errors may be negligible in most cases, but they can accumulate and impact the accuracy of the model, especially in situations where high precision is crucial.P

FAQ

What is the advantage of using STEP files?

STEP files offer interoperability, preserve geometry and associated data, are platform-independent, and are suitable for long-term archiving.

How to open a STEP file?

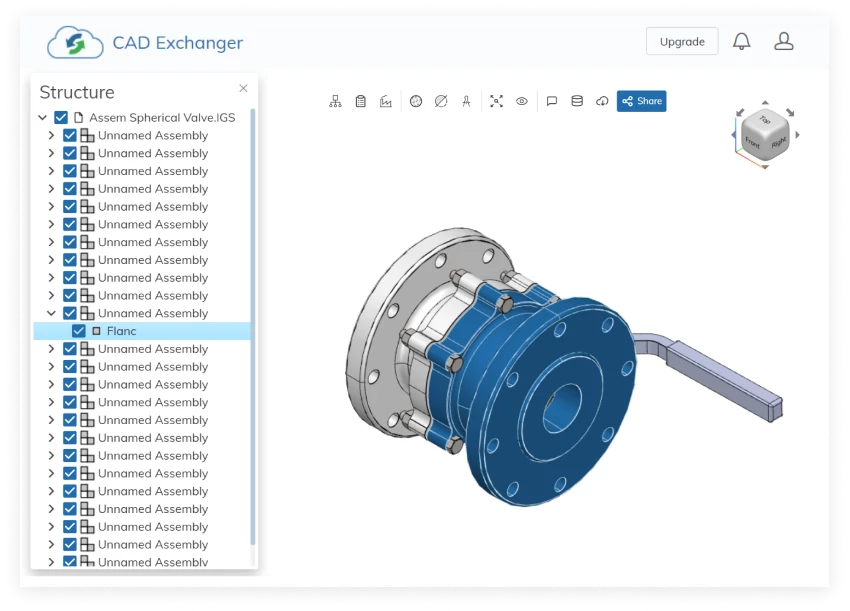

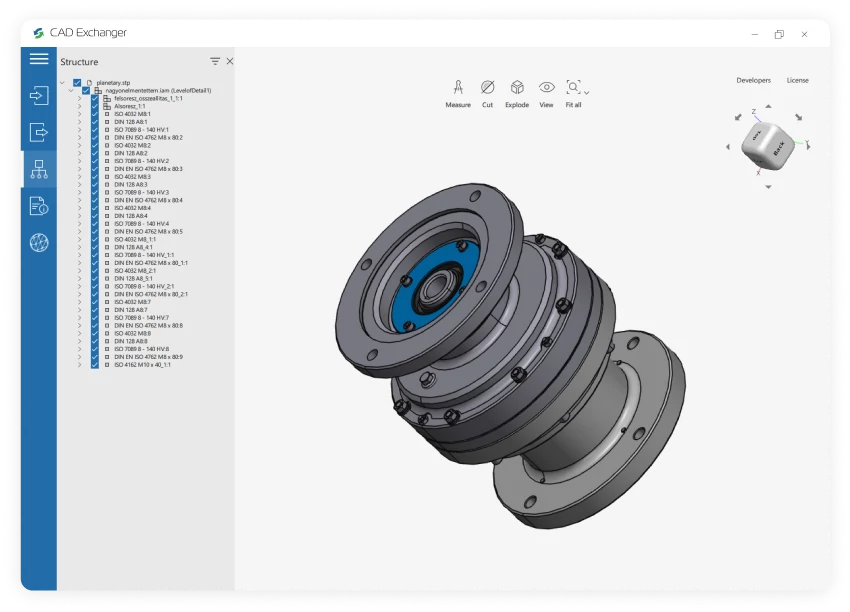

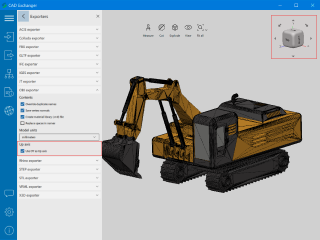

To open this file, you will need a compatible software application, for example, CAD Exchanger Lab. Launch the software and navigate to the 'New file' option. Browse your computer's directories and locate the STEP file you want to open. Then select the file and click "Open". Once the import process is complete, the file should be loaded into the software, allowing you to view and interact with the 3D model and associated data.

Are STEP files compatible with different CAD software?

Yes, STEP files are widely supported by various CAD software applications. They are designed to facilitate interoperability between different programs. See the full list in the 'STEP format is supported by' section.

History of STEP format

The history of this format dates back to the late 1970s when the need for a standardized method of exchanging product data between various CAD systems became apparent. To address this challenge, the International Organization for Standardization formed a committee, ISO TC 184/SC 4, dedicated to developing a universal format.

After years of collaborative effort from experts and industry stakeholders, the first version of the STEP standard, known as AP203, was released in 1994. It aimed to enable the exchange of data for mechanical and electrical designs. Over time, additional versions of the STEP standard were introduced, such as AP214 for automotive design and AP242 for complete product lifecycle information. These versions expanded the capabilities of STEP, accommodating various industry requirements and advancements in technology.

Today, the STEP file format is widely adopted and recognized as a reliable means of exchanging 3D models and associated data between different CAD systems. It has streamlined collaboration, enhanced interoperability, and improved efficiency across industries like automotive, aerospace, and manufacturing.

SOLIDWORKS

SOLIDWORKS is a proprietary format, used by the SOLIDWORKS software, a professional 3D CAD software application. It utilizes the file extensions ".sldprt" for part files and ".sldasm" for assembly files. In this format, all the necessary geometric information, features, dimensions, constraints, and other design data are stored to represent and document a 3D model.

Support of SOLIDWORKS in CAD Exchanger

CAD Exchanger can read files from version 2004 to version 2025. Such support includes:

- B-Rep representations;

- polygonal representations (except for versions 2004, 2007, and 2008);

- assembly structure via external files;

- configurations;

- names;

- user-defined properties;

- graphical PMI (versions 2015-2022);

- colors.

Follow this link to check out all the CAD Exchanger products.

Pros of the format

Comprehensive design information

The SOLIDWORKS format contains comprehensive design information. It includes not only the 3D geometry of the part or assembly but also feature history, dimensions, constraints, materials, and other design parameters. This level of detail allows for easy modification, analysis, and collaboration within the SOLIDWORKS ecosystem.

Widely used in engineering and manufacturing

SOLIDWORKS is a widely adopted CAD software, and its proprietary format is supported by various CAD tools, engineering applications, and manufacturing processes. This compatibility ensures seamless data exchange and collaboration between different stakeholders, such as designers, engineers, and manufacturers. Using the SOLIDWORKS format facilitates effective communication and streamlines the workflow throughout the product development lifecycle.

Cons of the format

Proprietary Format

The SOLIDWORKS format is proprietary, meaning it is owned and controlled by Dassault Systèmes, the company behind SolidWorks. As we wrote above, this format is widely used in engineering and manufacturing, but there are still softwares and tools that do not support SOLIDWORKS, due to its proprietary nature. While SolidWorks does provide options to export to various standard formats like STEP or IGES, the main challenge is that neutral formats do not contain all the design information, but only the final result of the design process. Also, there may be challenges in maintaining full fidelity and compatibility when working with other CAD systems.

Numerous ".sldprt" and ".sldasm" files

Managing a large number of files when working with complex models can become challenging, especially when it comes to transferring data. Some files can be lost or deliberately hidden. Without all the files together, the user only has an approximate model geometry in the form of a polygonal mesh, but all design information, including the exact geometry, is missing.

FAQ

What are SOLIDWORKS file extensions?

The file extension ".sldprt" is used for SOLIDWORKS part files. They are the building blocks of assemblies and are created and modified within the SOLIDWORKS environment.

For assembly files, SOLIDWORKS uses the ".sldasm" extension. Assembly files represent the coming together of multiple parts into a larger, functional unit. They are essential for visualizing and analyzing the interaction between different components.

Drawing files in SOLIDWORKS have the ".slddrw" extension. These files contain 2D representations of parts or assemblies. They enable the generation of design documentation suitable for further usage in product lifecycle, in particular they serve as blueprints for creating physical parts.

SOLIDWORKS also utilizes template files for creating new documents. Template files have the extensions ".prtdot" for part templates and ".asmdot" for assembly templates. These files define the default settings, styles, formats, and other parameters for creating a new part or assembly documents.

Additionally, SOLIDWORKS features a library feature functionality that allows users to create reusable design elements. Feature files for library features use the ".sldlfp" extension. These files define specific features that can be applied to parts or assemblies, saving time and effort by enabling the reuse of complex or commonly used design elements.

How to open SOLIDWORKS file?

To open this file, you will need a compatible software application, for example, CAD Exchanger Lab. Launch the software and navigate to the 'New file' option. Browse your computer's directories and locate the file you want to open. Then select it and click "Open". Once the import process is complete, the file should be loaded into the software, allowing you to view and interact with the 3D model and associated data.

History of SOLIDWORKS format

The SOLIDWORKS format history dates back to the early 1990s when SolidWorks brand was founded by Jon Hirschtick. The goal was to create a user-friendly, parametric 3D modeling software that would revolutionize the CAD industry.

In 1995, the first version of SOLIDWORKS was released, introducing a groundbreaking approach to 3D modeling. As SOLIDWORKS gained popularity, it expanded its capabilities and introduced new features with each subsequent release. The software focused on improving design efficiency, accuracy, and collaboration.

In 1997, Dassault Systèmes, a renowned software company, acquired SolidWorks Corporation, bringing SOLIDWORKS into its product portfolio. The SOLIDWORKS format has become a standard in the CAD industry.

Today, SOLIDWORKS remains one of the most widely used CAD software packages, serving millions of users worldwide. Its continuous development, integration with other technologies, and commitment to user-friendly design have solidified its position as a leading CAD solution in the industry.

From Our Blog

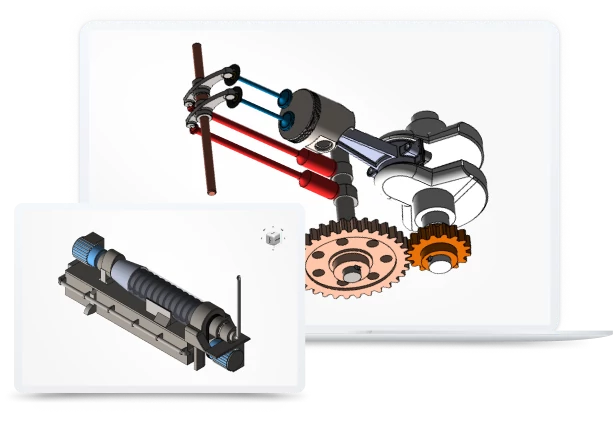

Everything you need to know about CAD file formats

A CAD file is an output of a CAD software, containing key information about the designed object: its geometry and topology representation, 3D model hierarchy, metadata, and visual attributes depending on the format of the file.

Read more

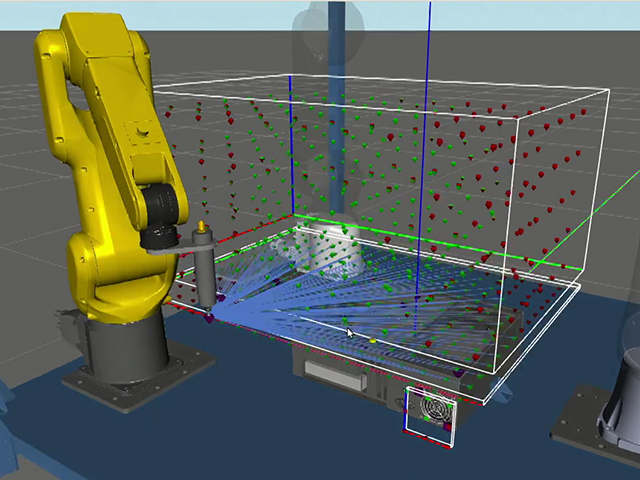

Realtime Robotics enhances responsive workcell monitoring by reading CAD files with CAD Exchanger

CAD Exchanger enables RapidSense and RapidPlan to read 3D CAD formats thanks to a unified API, fast data processing, adjustable meshing, and cancellation support.

Read more

3D XML and Solid Edge, broader versions coverage for CATIA, JT, Parasolid, and SOLIDWORKS mesh colors in CAD Exchanger GUI 3.10

Two new native formats and more possibilities in reading and writing CATIA, JT, Parasolid, SOLIDWORKS, Collada, FBX, GLTF, OBJ, and STEP.

Read more